Heating up a workpiece too quickly or too much may cause irreversible damage. A too gradual heating process will stall the workflow, while an insufficient heat supply will not do the trick. An important part of the right heating process is the monitoring of the temperature. There are different sensors available which do this. But which is the right one? And why? Let us help you!

Heating up a workpiece too quickly or too much may cause irreversible damage. A too gradual heating process will stall the workflow, while an insufficient heat supply will not do the trick. An important part of the right heating process is the monitoring of the temperature. There are different sensors available which do this. But which is the right one? And why? Let us help you!

TM Induction Heating has chosen to use K-Type sensors. These thermocouples normally consist of two dissimilar metal wires, joined at one end and connected to the equipment at the other end. But as our induction heaters are only used on ferrous materials, we use a special version equipped with a magnet, which keeps the sensor in place during the heating process.

So far, so good. But as the temperature rises, the magnetizing force decreases. Thus if the highest temperatures are to be monitored accurately, a thermocouple which stays in place – even with less magnetizing force – is needed. To this end, we have developed thermocouples with more powerful magnets and thermocouples with a clamp.

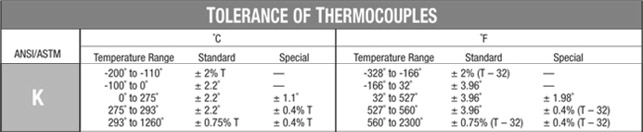

Our K-Type sensors are nickel based and therefore very cost-efficient. They are ideal for operation in oxidizing atmospheres, making them the right choice for use with the induction heating equipment. Please see the table below for an indication of the accuracy of the sensors.

The sensor monitors the temperature of the object. This precision allows for a sure and controlled heating process, with datalogging for optimal process documentation. Even more control can be achieved with a two-sensor heating process. This ensures a closely guarded Delta-T between the two sensors, thus enabling an even distribution of heat over the workpiece. This puts you in ultimate control of the process. Exactly what one wishes when using expensive bearings, couplings, bushings etc.

The sensor monitors the temperature of the object. This precision allows for a sure and controlled heating process, with datalogging for optimal process documentation. Even more control can be achieved with a two-sensor heating process. This ensures a closely guarded Delta-T between the two sensors, thus enabling an even distribution of heat over the workpiece. This puts you in ultimate control of the process. Exactly what one wishes when using expensive bearings, couplings, bushings etc.

Thus the sensor needed is dependent on the maximum temperature range to be worked with, plus the measure of control needed over the distribution of heat. A higher temperature requires a heavy-duty magnet or clamping sensor. More control means more sensors. For some applications, we may even build customized equipment with four sensors – depending on the needs of your particular process.