High tech products require high tech production methods. For a production facility of four-wheel drive luxury automobiles one of our customers required an integrated solution for the heating of bores during assembly. Their simple and clear description of the request: “We want a gradual, uniform, quick and silent heating method for our gears and synchro groups.”

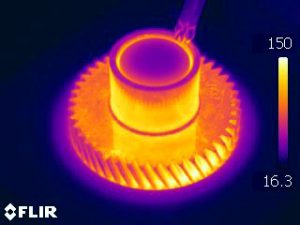

The specific project at hand concerns an automatic eight speed transmission, meaning we needed eight separate heating stations, integrated in the production line. Only the bores need to be heated, with as little depth penetration of the heat as possible. The teeth of the gears have been thermally toughened beforehand and this process should not be interfered with.

After performing several experiments, we engineered a solution using water-cooled mid frequency heaters – 230 V / 16 A – and tested on the actual parts. The quality assurance department of our customer subsequently put these parts to metallurgical tests to see if the material integrity was unchanged and the previous toughening had not been compromised.

Each station heats one component of the gearbox using a custom-made coil. Gear wheels and synchromesh are mounted at respectively 170 °C in 60 seconds and 80 °C in 35 seconds. Very specific, just as we like it.

After the ‘go ahead’, we developed a 100% flexible system where heaters can be added, unplugged and exchanged. This enables the customer to adjust the setup, should new models require a different strategy. For example, these automobiles may in the future be fitted with nine speed transmissions. The adjustment of the heating stations is a simple task thus offering long-term maximum usability.

With each station the operator has a dedicated touchscreen to activate, control and monitor the heating process. The operator receives the specific mounting and heating instructions on this screen, ensuring the right instructions are given with each component. Using a water-cooled station offers another advantage: it allows for continuous operation.

Our solution does the job more accurately than the previously used low frequency method and is not only more flexible and energy efficient, but also ensures quick and secure change-overs: The heating stations are equipped with quick release connections.

The TM Induction Heating stations have a minimal equipment and environmental footprint, operate relatively silent and need little maintenance.

We would like to reveal a little secret: our equipment may be high tech, but the heating principle is a proven, robust and basic technique. We just specialize in it. That is what sets us apart.