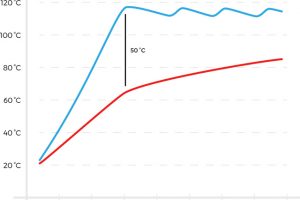

Increased heating quality of metallic workpieces with a central opening and round closed form This article describes a newly developed method by TM Induction Heating for induction heating devices. It increases the quality of heating metallic workpieces that form a closed round shape with a central opening (bearing, gears, etc.). Throughout the entire warming process, both the temperature of the inner and outer regions are continuously monitored. ... Continue reading about Dual Sensor Technology

Induction Heating 101 – free whitepaper

Basics of Induction Heating “Induction heating is a physical phenomenon in the area of electromagnetism. It involves the heating of an electrically conducting object (a metal or a material such as carbon or graphite) by electromagnetic induction. An oscillating magnetic field in an electromagnet, the primary coil, induces so-called eddy currents in a short-circuited secondary circuit. This circuit is the workpiece, i.e. the object to be heated. ... Continue reading about Induction Heating 101 – free whitepaper

Tricks of our Trade: Sensors

Heating up a workpiece too quickly or too much may cause irreversible damage. A too gradual heating process will stall the workflow, while an insufficient heat supply will not do the trick. An important part of the right heating process is the monitoring of the temperature. There are different sensors available which do this. But which is the right one? And why? Let us help you! TM Induction Heating has chosen to use K-Type sensors. These ... Continue reading about Tricks of our Trade: Sensors