2 Sensor Technology

TM Induction Heating offers the industry, maintenance service and repair shops the right tools for stress-free induction heating of critical parts, in order to prevent decreased quality caused by using wrong heating methods. This will support users to guarantee the reliability of their service, the reliability and lifetime of the specific part, and in turn the complete application.

Generally, induction heating is the preferred alternative to heating methods that involve a gas torch, oil bath or furnace. Induction heating is safer, cheaper, and greener. The efficiency of an induction heater results in a very fast temperature increase, introducing a risk for unequal heating. Large temperature differences can cause thermal and mechanical stress, resulting in irreversible damage to the part.

Thermal stress is an issue with heating gears. Thermal expansion causes no problems as long as the material can expand freely. If the material cannot expand freely, it can deform the gear and result in a changed metallurgical structure.

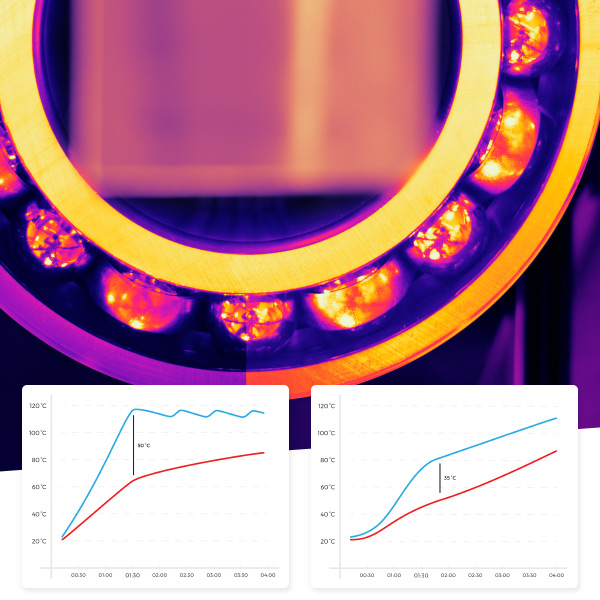

Mechanical stress is a phenomenon when heating bearings too fast. A large temperature difference between the inner and outer ring can press the balls or rollers into the rings and cause (invisible) irreversible damage.

It is absolutely crucial to control the maximum ΔT during a heating cycle.

SURETHERM 2 Sensor Control

Although the actual programming and logarithms are rather complicated, the basics of 2 Sensor Temperature control is simple. The software of our SURETHERM heaters constantly monitors the actual ΔT and the actual temperature increase of both sensors. Based on these values, the software regulates the power output of the induction heater.

When the trend of the heating curve predicts an overshoot of the maximum (set) ΔT the induction heater will decrease the power output. The power will increase as soon as the changing trend allows it again. The power is constantly changing step-less on a scale of 0-100%. The result: Guaranteed safe, equal and stress-free heating cycles within the shortest time possible.

Operation of 2 Sensor Heating Mode

The operation of the 2 Sensor Heating Mode is simple and straightforward on the touchscreen of our SURETHERM series. Plugging in the second sensor enables 2 Sensor Heating Mode. A feature called Auto Sensor Select recognizes the outer and inner sensor automatically.

During the heating cycle set-up, the required maximum allowed ΔT can be set. Various parameters are available during the heating cycle; Actual Temperature, Actual Power, Set ΔT, Set Temperature, Actual ΔT, and Total Heating Time. After a completed heating cycle, the data can be saved to a USB drive to document your quality control process.

History & development of 2 Sensor Technology

TM Induction Heating was the first and still is the only manufacturer of low frequency induction heaters with a properly controlled heating mode with 2 sensors. It was Hansen Industrial Gearboxes who discovered a shortened product lifespan of the gearwheels used in their gearboxes, which are mounted in wind power applications. Research showed them metallurgical damage occurred in the gearwheels, caused by uneven heating of the gearwheels during the shrink-fit assembly process.

Hansen contacted TM Induction Heating with a specific request to develop an induction heater that could control the ΔT between the inside bore and outside part of the gear. Back in 2008, the request resulted in adding the 2 Sensor Technology feature to the existing induction heaters at Hansen’s factory.

Integrating 2 Sensor Technology into our standard induction heaters was one of the objectives incorporated in our development of the SURETHERM series. Since the project with Hansen we knew that stress-free heating is the right heating method. Leaders in bearing industry agree on using 2 Sensor Technology, confirming the importance of stress-free heating. In a modern world where quality standards are increasing, controlled heating of critical parts is becoming a general requirement for assembling procedures in all industries.

TM Induction Heating’s 2 Sensor Technology is unique in the market. Other manufacturers might claim to offer a heating mode similar to 2 Sensor Mode, but monitoring the ΔT is not the same as controlling the maximum ΔT.